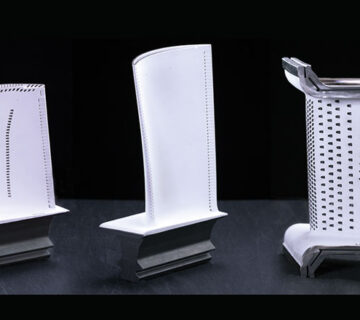

Frame 7EA – 1st, 2nd, 3rd Stage Buckets

The Frame 7EA buckets achieve high-temperature performance up to 2055 °F with the application of world-class metallic-bond coating and thermal barrier coating (TBC).

7EA 1st Stage Buckets:

•Manufactured with an equiaxed nickel-base proprietary superalloy

that greatly enhances the life of the part

• Coated with a proprietary coating to ensure superior oxidation resistance at typical firing temperatures

• Includes an internal aluminide coating

7EA 2nd Stage Buckets:

•Manufactured from an equiaxed nickel-based proprietary superalloy with an MCrAly coating to provide superior protection against oxidation, creep, and thermal-mechanical fatigue cracking

• The design incorporates improvements to shroud geometry that reduce weight and improve part life

• The design has eliminated the use of the cutter tooth and applied an abrasive rail coating, thus further reducing weight, improving creep life, and improving sealing effectiveness at the shroud block interface

7EA 3rd Stage Buckets:

• Manufactured with equiaxed nickel-based proprietary superalloy that provides protection against oxidation and thermal-mechanical fatigue cracking

• Improvements to shroud and airfoil geometry reduce weight and extend part life

• The design has eliminated the use of the cutter tooth, applied an abrasive rail coating, and improved sealing effectiveness at the shroud block interface